GAPS 2.5.2 Table 1 Inter-Unit

Equipment 1:

Equipment 2:

| Unit | Unit_1 | Inter Unit Spacing (ft) | Inter Unit Spacing (m) |

|---|

GAPS 2.5.2 Table 2 Intra-Unit

Equipment 1:

Equipment 2:

| Unit | Unit_1 | Inter Unit Spacing (ft) | Inter Unit Spacing (m) |

|---|

PTS 12.03.04 Layout of Onshore

Equipment 1:

Equipment 2:

| Unit | Unit_1 | Inter Unit Spacing (ft) |

|---|

| LEGEND: | |

| Input Data | |

| Output |

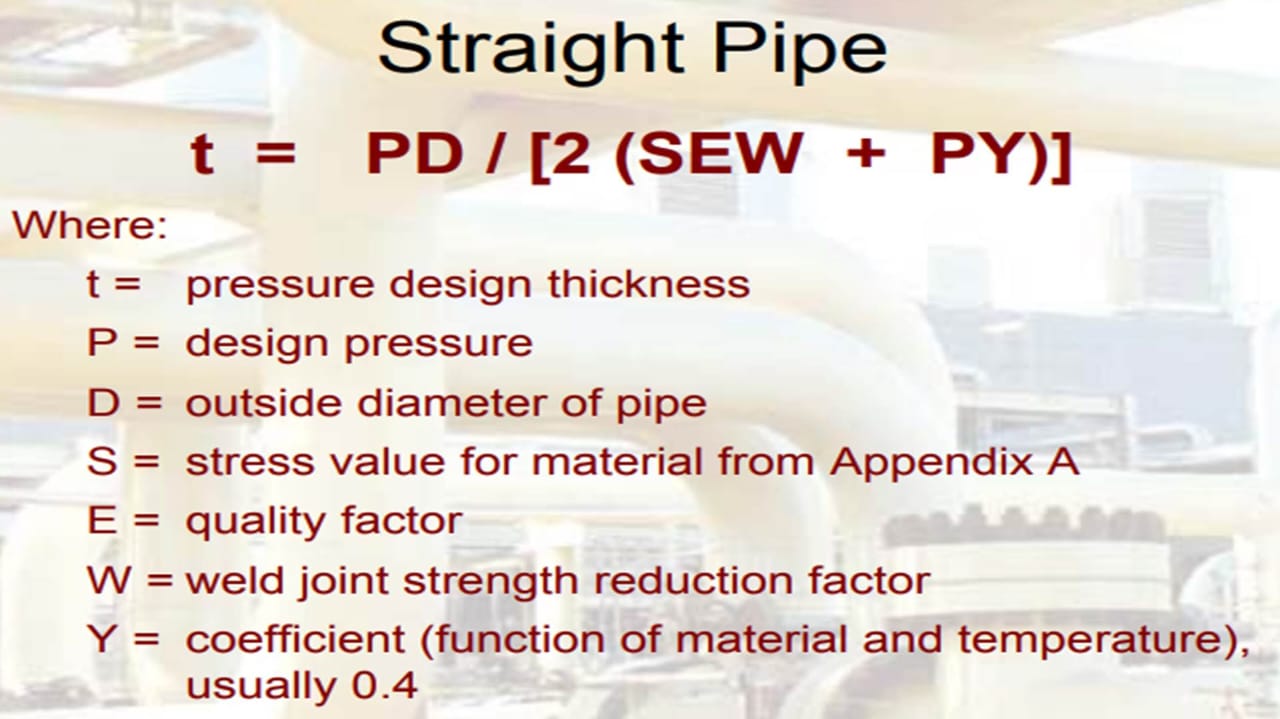

ASME B31.3 Wall Thickness Calculation

|

|

|

|

|---|---|---|

| Pipe Material | ||

| Design Pressure | PSI | |

| Outside Diameter | mm | |

| Stress Value for Material from ASME B31.3 Table A-1 or Table A-1M, S | psi | |

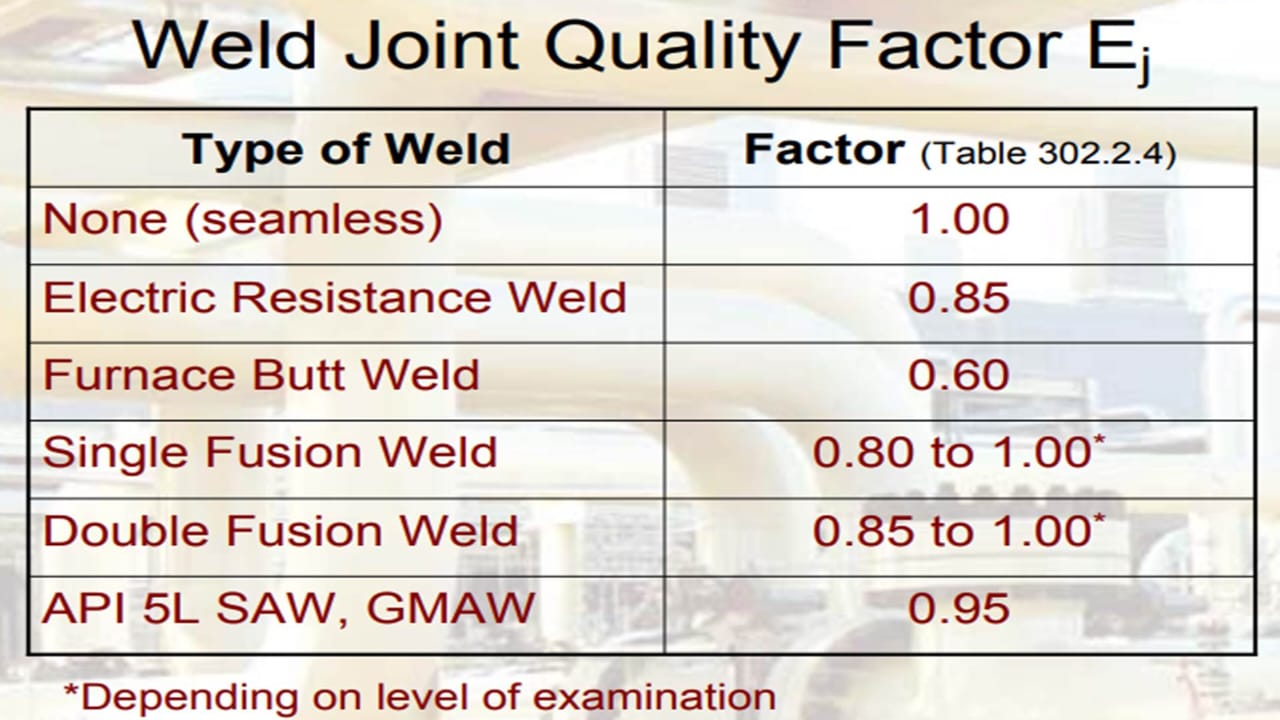

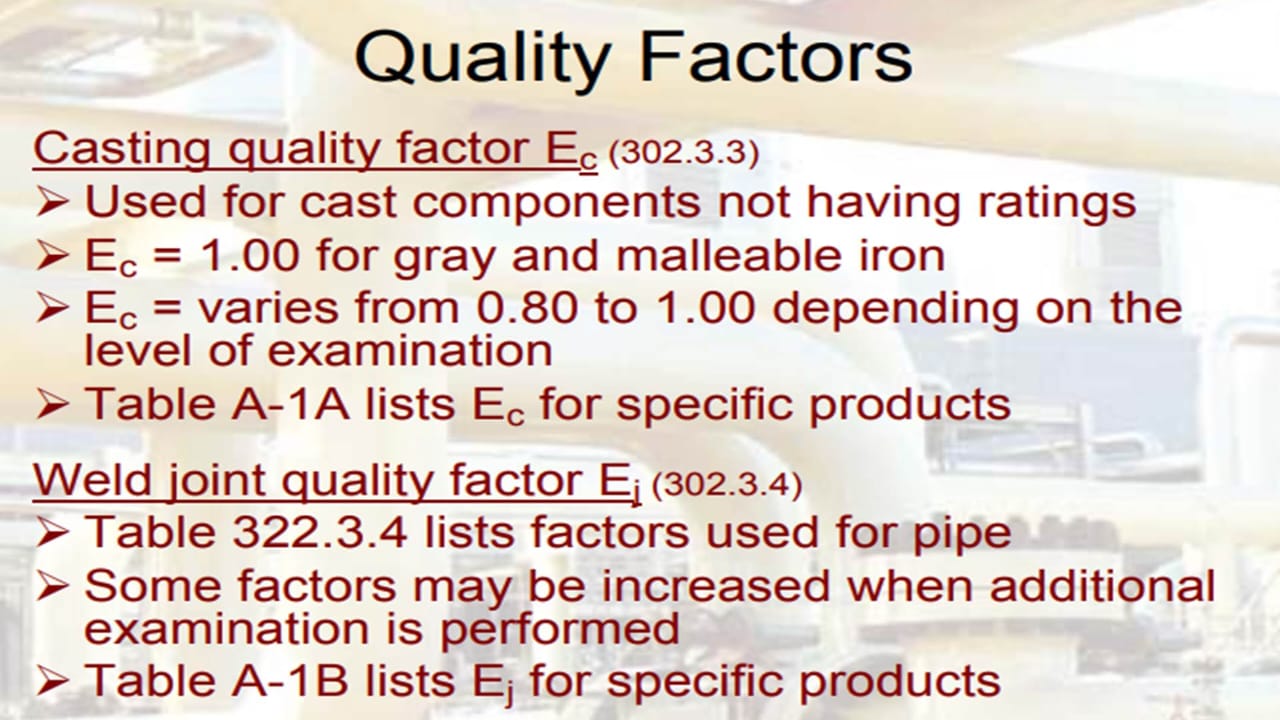

| Quality Factor (E) | ||

| Weld Joint Strength Reduction Factor, W | ||

| Coefficient, Y | ||

| Corrosion Allowance, CA | mm | |

| tmin: | mm | |

| tmin + CA: | mm | |

| trequired: | mm | |

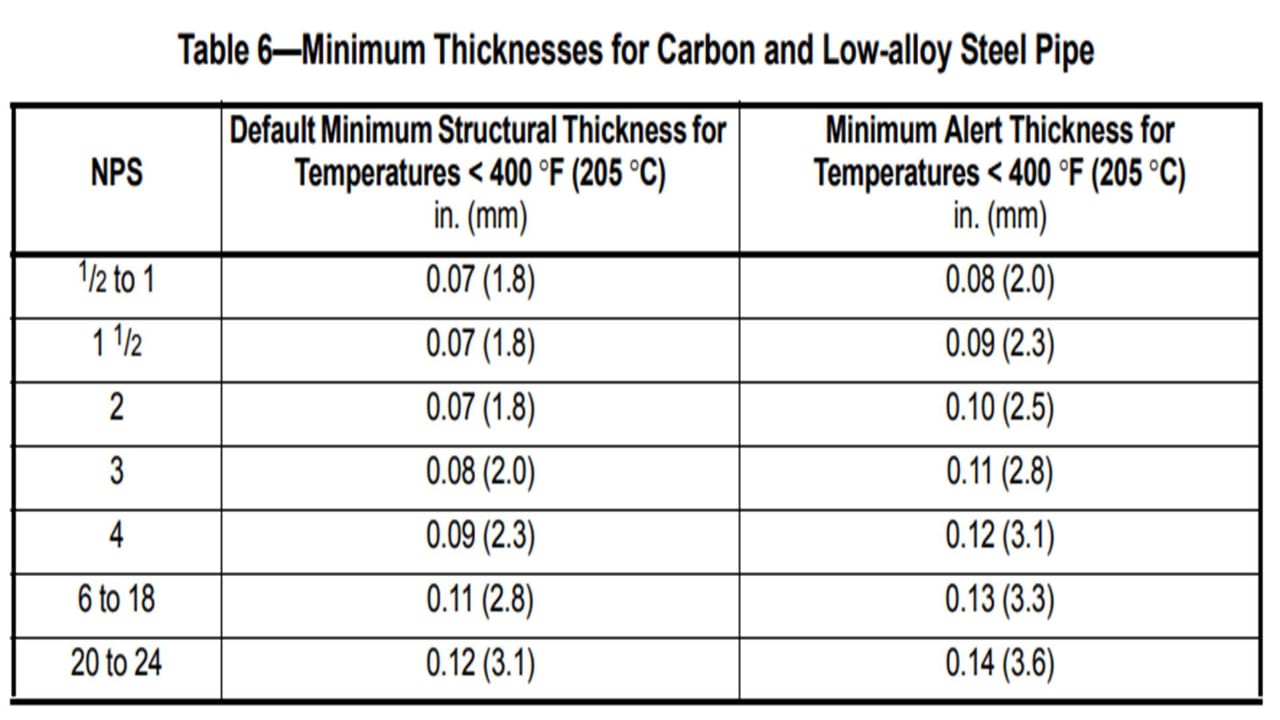

| Minimum Alert Thickness (API 574) | mm |

| LEGEND: | |

| Input Data | |

| Output |

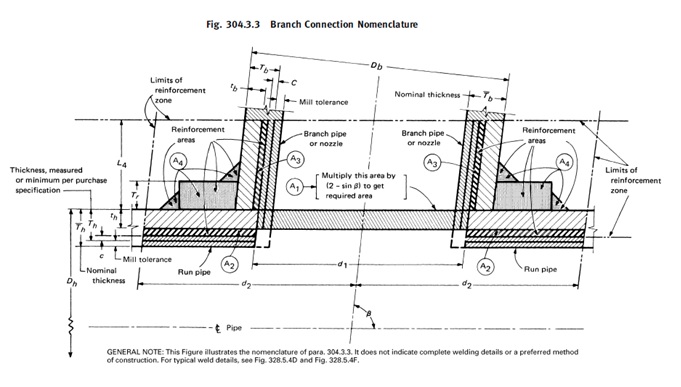

ASME B31.3 Para. 304.3.2 Branch Connection

|

|

|

|

|---|---|---|

| Nominal Pipe Size, Dh | mm | |

| Wall Thickness, WT | mm | |

| Run Pipe Thickness, Th (WT)(Mill Tolerance) | mm | |

| Corrosion Allowance, C | mm | |

| Mill tolerance, MT | % | |

| Material | ||

| Stress Value (from Table 1), S | psi | |

| Coefficient from Table 304.1.1 provided t < D/6, Y | ||

| Quality Factor, E | ||

| Weld Joint Strength Reduction Factor, W |

|

|

|

|

|---|---|---|

| Nominal Pipe Size, Db | mm | |

| Wall Thickness, WT | mm | |

| Run Pipe Thickness, Th (WT)(Mill Tolerance) | mm | |

| Corrosion Allowance, C | mm | |

| Mill tolerance, MT | % | |

| Material | ||

| Stress Value (from Table 1), S | psi | |

| Coefficient from Table 304.1.1 provided t < D/6, Y | ||

| Quality Factor, E | ||

| Weld Joint Strength Reduction Factor, W |

|

|

|

|

|---|---|---|

| Design Pressure, P | psi | |

| Design Temperature, T | °C | |

| Smaller angle between axes of branch and run, β | degree | |

| Nominal Thickness of Reinforcing Pad, Tr | mm |

|

|

|

|

|---|---|---|

| Header Nominal Thickness, th | mm | |

| Branch Nominal Thickness, tb | mm | |

| Effective Length Removed from Pipe at Branch, d1 | mm | |

| Half Width of Reinforcement Zone, d2; d2=d1 or whichever greater | ||

| Final d2 value | mm | |

| Required Reinforcement Area, A1 | mm2 | |

| Area Resulting From Excess Thickness in the Run Pipe Wall, A2 | mm2 | |

| L4 (assuming no reinforcement pad) | ||

| L4 | ||

| Area Resulting From Excess Thickness in the Branch Pipe Wall, A3 | mm2 | |

| tc = 0.7Tb or 6mm, whichever is less | ||

| Final tc value | mm | |

| A4 | mm2 | |

| The total available area (A2+A3+A4) | mm2 | |

| FINAL OUTCOME | ||

| NOTES: A2+A3+A4 < A1 | Reinforcement pad required | |

| NOTES: A2+A3+A4 > A1 | No reinforcement pad is required |

| LEGEND: | |

| Input Data | |

| Output |

Bending Stress - Pipe Support Adequacy Check

|

|

|

|

|---|---|---|

| Outside Diameter (D) | mm | |

| Outside Diameter (D) | m | |

| Wall Thickness | mm | |

| Wall Thickness | m | |

| Weight of Concentrated load | kg | |

| Weight of Pipe per meter | kg/m | |

| Water Weight per meter | kg/m | |

| Allowable Stress (Sa) | Pa | |

| Modulus Elasticity (E) | Pa | |

| Moment of Inertia (I) | mm4 | |

| Pipe Span (L) | m | |

| Hydrotest Weight (pipe+water) | kg/m |

|

|

|

|

|---|---|---|

| Concentrated load at any point | ||

| Maximum Deflection (∆max) | m | |

| (𝑃𝐿3)/48𝐸 | mm | |

| Allowable Deflection | m | |

| L/500 | mm | |

| Bending Stress | Pa | |

| 𝑃𝐿𝐷/8𝐼 | MPa | |

| Uniform distributed load | ||

| Maximum Deflection (∆max) | m | |

| (5𝑊𝐿4)/384𝐸𝐼 | mm | |

| Deflection Ratio | ||

| Maximum Deflection/Allowable Deflection | ||

| Bending Stress | Pa | |

| (𝑊𝐿2 𝐷)/16𝐼 | MPa | |

| Maximum Deflection (5𝑊𝐿4/384𝐸𝐼)+(𝑃𝐿3/48𝐸𝐼) |

mm | |

| Maximum Bending Stress (𝑃𝐿𝐷/8𝐼)+(𝑊𝐿2𝐷/16𝐼) |

MPa | |

| LEGEND: | |

| Input Data | |

| Output |

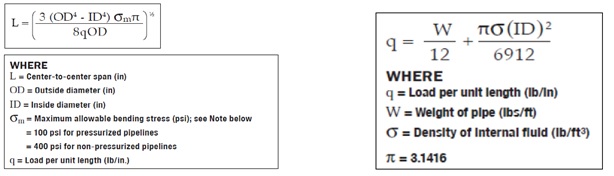

SUSPENSION LENGTH

| Description | DN | |

|---|---|---|

| PN | ||

| Average Wall Thickness (mm) | t (avr) | |

| Weight of Pipe (kg/m) | W | |

| Outside Diameter (mm) | OD | |

| Inside Diameter (mm) | ID | |

| Maximum Allowable Bending Stress (psi) | Ꝋ | |

| Density of Water (kg/m3) | Ბ | |

| Pi | ∏ |

| Description | DN | |

|---|---|---|

| PN | ||

| Average Wall Thickness (mm) | t (avr) | |

| Weight of Pipe (ib/ft) | W | |

| Outside Diameter (in) | OD | |

| Inside Diameter (in) | ID | |

| Maximum Allowable Bending Stress (psi) | Ꝋ | |

| Density of Water (ib/ft |

Ბ | |

| Pi | ∏ |

| Load per unit Length (ib/in) | q | |

|---|---|---|

| Pipe Support Span Length (in) | L | |

| Pipe Support Span Length (m) | L |

| LEGEND: | |

| Input Data | |

| Output |

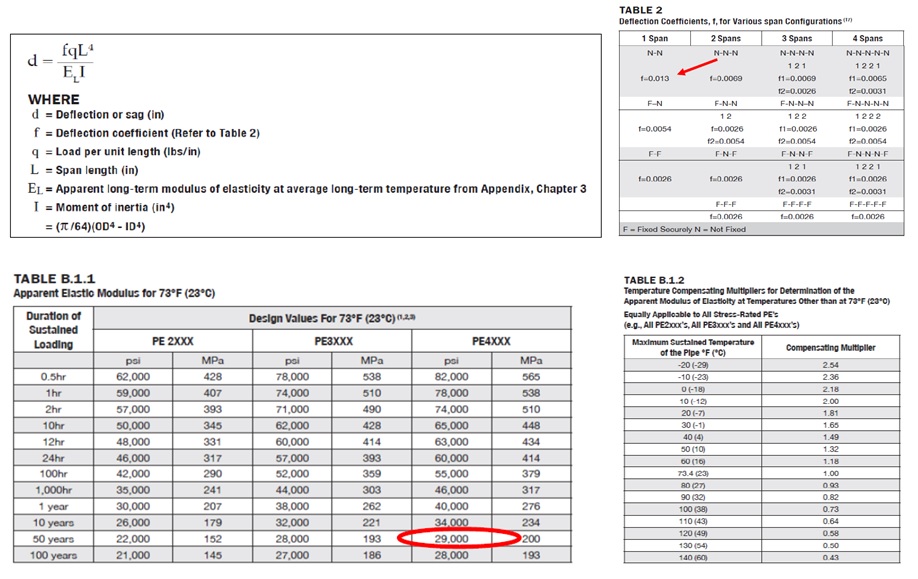

DEFLECTION VALUE

| Outside Diameter (in) | OD | |

|---|---|---|

| Inside Diameter (in) | ID | |

| Pipe Support Span Length (m) | L | |

| Description | DN | |

| NB | ||

| PN | ||

| Deflection Coefficient | f | |

| Load per unit Length (ib/in) | q | |

| Pipe Support Span Length (in) | L | |

| Apparent Long-Term Modulus of Elasticity | EL | |

| Moment of Inertia | I |

| Pipe Deflection (in) | d | |

| Pipe Deflection (mm) | d |